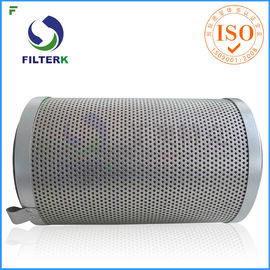

FILTERK OM/120 Centrifugal Compressor Air Oil Seperator Filter

Why use Air Oil Separating Filter Element ?

- Oil smoke is hazardous to your health.

- Oil smoke causes slippery floors and collects oil and dust on machines and walls.

- Oil smoke can lead to coating in ventilation pipes, a potential fire risk, and in heat exchangers, so reducing the efficiency of heat recovery.

- The cutting oil which drains from the filter can be reused.

- The amount of oil smoke polluted air discharged must not exceed the prescribed limits.

Air compressors and oil

Air compressors are used in a variety of industrial settings, including construction, manufacturing

and engineering processes. These devices require oil to cool the mechanism during operation,

lubricate moving parts and seal the system to prevent air leakage. However if the oil used for the

above purposes becomes mixed with the air used in the compressor, everything from the

distribution network to the production equipment may be negatively impacted. This is why an air oil

separator filter is an essential part of any compressed air system.

The air-oil separation process

In compressed air systems, the majority of the oil is removed by centrifugal force. The remaining

amount, which consists of small droplets and mist, must be separated out by an air oil separator

filter. Installed in the compressor’s air receiver tank, this filter is made of layers of borosilicate glass

fibers which remove the residual oil from the air stream. Basically, fine oil droplets are strained

through the filter medium and as they move, they coalesce to create larger drops. Gravity induces

these drops to move downward, where they collect at the bottom of the separator. They are then

sucked back into the air compressor’s oil sump and reused in the system. The compressed air,

cleaned of oil residue, continues on to the air receiver.

Types of air oil separator filter

There are a variety of different air oil separator filter designs available on the market. The wrap type

is the original design used to separate oil droplets from compressed air streams. It consists of a flat

layer of borosilicate glass fibers wrapped around a central tube. Pleated air oil separators filter

have a larger surface area due to their pleated filter medium and because of this can typically

handle an air flow capacity which is double that of the wrap type. Deep filter air oil separators also

provide a better capacity than wrap filters. They accomplish this by incorporating up to three

different grades of glass fiber, which are attached to the support tube in greater quantities than is

the case with wrap separators. The capacity of this type is about equal to that of pleated air-oil

separators. Meanwhile, spin on separators consist of a combined unit made up of filter medium and

housing. This makes it easier to replace during maintenance.

Filterk has the solution!

-

FILTERK OM/120 air compressor oil smoke eliminator elements have been designed to guarantee more than 99.9% separation of particles down to 0.3µm. The separating efficiency remains constant and does not deteriorate over time.

-

It far exceeds today's legal requirements and FILTERK OM/120 air compressor oil smoke eliminator element is therefore a sound investment for the future.

FAQ:

1. Q:Are you a factory or trading company?

A:We are a factory

2. Q:Where is your factory located? How can I visit there?

A:Our factory is located in Zhangjiagang City, Jiangsu Province, China, about 1.5 hours from Shanghai and

40 minutes from Wuxi Dong station by car. All our clients, from home or abroad, are warmly welcome to visit us!

3. Q:How can I get some samples?

A: We are honored to offer you samples.

4. Q:How does your factory do regarding quality control?

A:Quality is priority. Filterk people always attach great importance to quality controlling from the very beginning

to the very end. Our factory has gained ISO9001:2008 authentication.

We are your best choice!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!