FILTERK Pleated dust collector filter bags and cartridges

The pleated filter bags and cartridges are an innovation over the conventional filter bags to address market requirements of higher efficiency and lower bag filter space requirement. These products are made up of spun bonded polyester, which works on the “surface filtration technology”. As the media is assembled in a pleated fashion, it provides 3 to 4 times higher filtration area compared to conventional bags.

Application Industries

Cement, Steel, Metallurgical, Power Plants, Gypsum, Cupola, Ceramics, Incinerators, Paints, Pharmaceutical, Asphalt Mixing, Fertilizers, Spray Dryers, Sugar, Asbestos, Powder Coating, Shot Blasting, Wood Working, Food Processing, Foundry, Welding Fumes.etc

Filter Materials Available:

- More filter material you can choose

- 100% cellulose (H&V material)

- 80% cellulose+20%polyester (H&V material)

- 80% cellulose+20%polyester Flame retardant (H&V material)

- Polyester(white,black for choose)

- Polyester+Flame retardant

- Polyester+oil,water resistant

- Polyester+Anti static

- Polyester+PTFE membrane+Anti static

- Polyester+PTFE membrane

- Nano-web

- Nano-web Flame retardant

Application environment of PU Molded Pleated Bag Filter

| 1. Cement and rock |

|

Crush/Grind Coal mill Raw mill/Cement mill Clay crushed

Packaging machine Bentonite crushed Kaolin processing

Ventilation and dust removal of silo top Material handling / shipping

|

| 2. Aluminum plant |

|

Fluidized bed dry-cleaning tower The venturi jet dry-cleaning tower

Self-baking dry-cleaning tower Carbon dust processing

Broken and ventilation of anode Reaction / non-reaction mine shafts prebaked

|

| 3. Food / Medical |

|

Food Additives Cereal drying Protein spray drying Grain processing

Flour Animal vitamins Sugar-coated tablets

|

| 4. Metallurgy |

|

Electric arc furnace Blast furnace Sulfur removal furnace Casting machine

Induction furnace Mold cooling line Blasting / Polishing Drum furnace

Sand production/recycling

|

| 5. Chemical industry |

|

Fertilizer spray drying Plastic fiber Bleaching powder Cellulose

Polyethylene resin Polystyrene staple Coke / briquettes processing Packaging line

Tire / Special rubber PVC Catalyst processing

|

| 6. Paint / Pigment |

|

Black powder mixing / agitation Packaging line Pneumatic conveying Paint mixing

Pigment stir Spray drying Micro powder mill

|

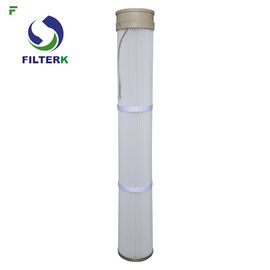

FILTERK Cylindrical Polyester Dust Collector Bottom Loader Pleated Bag

Feature of Dust Collector Bottom Loader Pleated Bag :

u 100% fine sand bonded polyester

u Wide and shallow pleated

u A variety of specifications for customers to choose

u Filtration efficiency up to 99.99%

u Integrated design,quick and easy installation, maintenance

u Suitable for a variety of tube sheet specifications

u Top and bottom are pouring with special materials

u Surface can be special treatment, like PTFE coating, anti-static etc.

| Part # |

G1810-DL |

| Structure |

Cylindrical Bottom Loaded Filter Cartridge |

| Dimension |

(OD)151*(ID)84*(H)1000 mm |

| Filter Material |

Polyester |

| Efficiency |

100% (Particles ≥5μm) |

| Top Cap |

Molded polyurethane (PU)-soft |

| Bottom Cap |

Galvanized |

| Inner Core |

Galvanized diamond mesh |

| MOQ |

NO MOQ . But advice full container to save cost.

20GP FCL: 811 pieces

40GP FCL: 1623 pieces

40HQ FCL: 1893 pieces

|

| Loading Port |

Shanghai |

| Lead Time |

Around 10 days for 20GP container |

| Payment |

T/T ; West Union ; Paypal |

| Shipment |

By sea to your nearest port

By air to your nearest airport

By express (DHL,UPS,FEDEX,TNT,EMS) to your door

|

| Package |

Carton |

| Max Capacity |

Around 1000 pcs per week |

Our Factory provides alternative filters to well know dust collectors using bottom loader cartridges. Our Bottom Loader Pleated Bag cartridge is installed from the dirty side using a soft polyurethane top cap.

It is suitable for air filtration of dust and fumes from cement, metal/aluminum, food & beverages, woodwork, chemicals, powder coating, plasma/laser cutting, sandblasting, textiles, welding and casting.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!